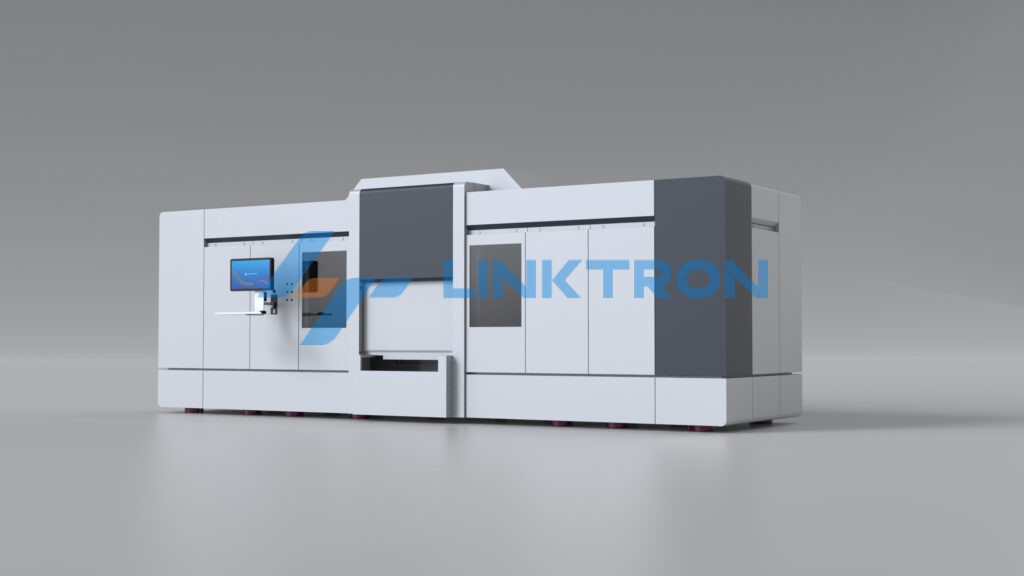

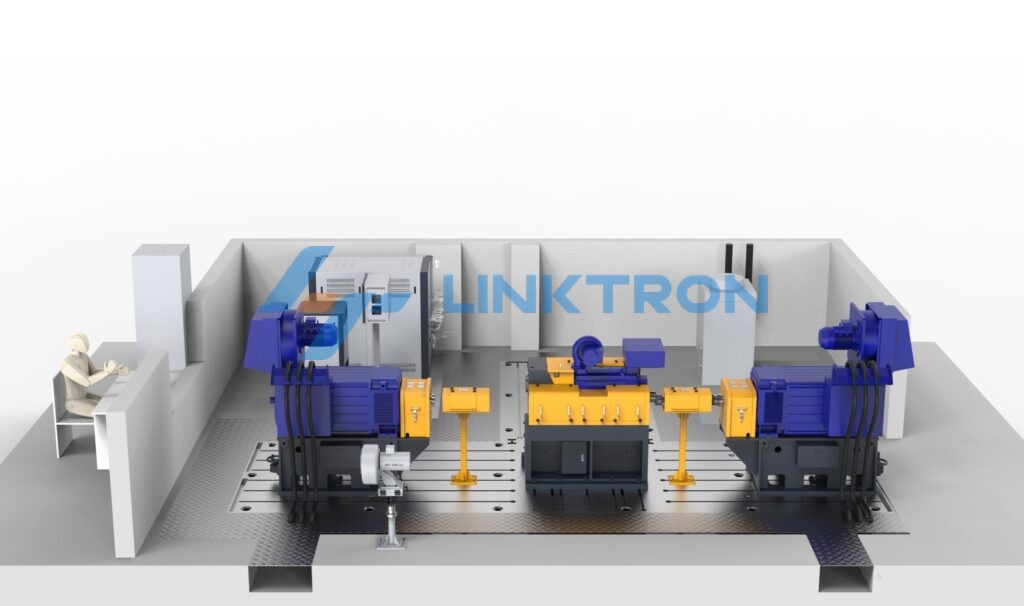

The automotive inverter is a critical component of electric vehicles, responsible for converting DC power from high-voltage batteries into AC power to drive the motor and provide necessary power. By precisely controlling the motor’s speed and torque, the inverter enables acceleration, deceleration, and braking functions. During braking or deceleration, the inverter converts AC power back to DC, recharging the battery and achieving energy recovery. We offer diverse process solutions, including assembly and testing, tailored to specific customer requirements for inverter products. Our flexible, discrete assembly processes and designs can adapt to various testing production needs. These solutions are highly scalable and versatile, meeting a wide range of engineering application requirements.