A turbocharger is a mechanical device aimed at improving engine performance. Its working principle is to use the exhaust gas energy emitted by the engine to compress the intake air, increasing the oxygen content in the combustion chamber, and enabling it to burn more fuel and achieve higher power output. The structure of a turbocharger mainly includes three core components: compressor wheel, turbine, and central shaft. When the exhaust gas is discharged from the engine and flows through the turbine, the turbine rotates accordingly, and the compressor wheel is driven by the central shaft to rotate. The compressor wheel sucks in air, compresses it, and then delivers the compressed air to the combustion chamber of the engine. Thanks to the increase in air pressure and temperature during the compression process, the operational efficiency and overall performance of the engine will be significantly enhanced.

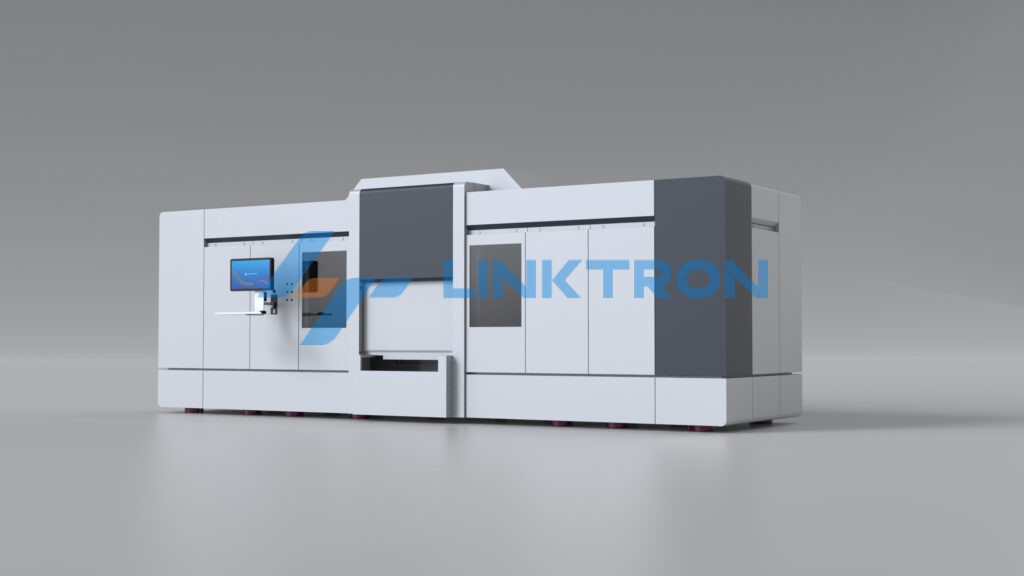

Linktron can provide high-precision, high-standard fully automated assembly and testing solutions based on the characteristics of turbochargers of different specifications.